Category

ComplianceCreation date

Employers are responsible for providing a safe and healthy workplace for their employees.

If the workplace contains a space that may be large enough for an employee to enter and work in, and the configuration will hinder the activities of an employee who must enter into, work in or exit from the space, the space is considered a “confined space.”

A Permit-Required Confined Space contains Health or Safety Hazards.

Need help with your next confined space entry project? Contact us now and let us put our expertise to work for you!

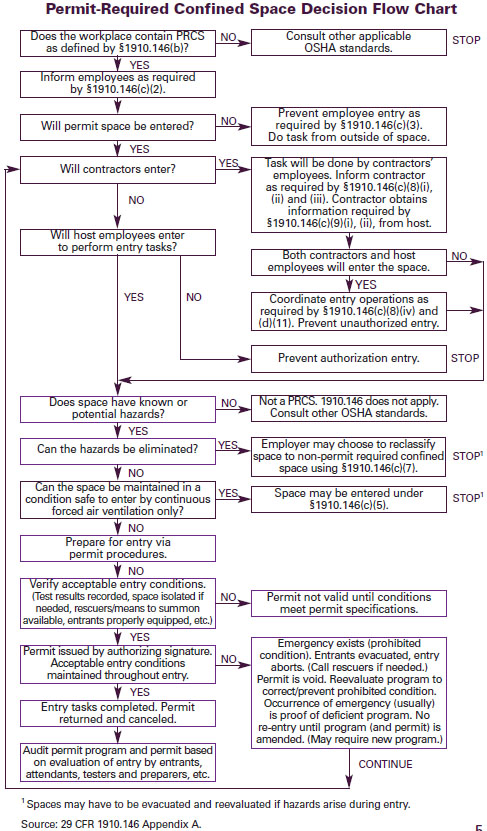

One of the basic safety requirements with entering a confined space, such as a tank, is to evaluate if the tank is a Permit-Required Confined Space, PRCS.

By definition, a confined space (29 CFR 1910.146(b)):

- Is large enough and so configured that an employee can bodily enter and perform assigned work; and

- Has limited or restricted means for entry or exit (for example, tanks, vessels, silos, storage bins, hoppers, vaults, and pits are spaces that may have limited means of entry.); and

- Is not designed for continuous employee occupancy.

By definition, a permit-required confined space has one or more of these characteristics (29 CFR 1910.146(b)):

- Contains or has the potential to contain a hazardous atmosphere;

- Contains a material with the potential for engulfing an entrant;

- Has an internal configuration such that an entrant could be trapped or asphyxiated by inwardly converging walls or by a floor which slopes downward and tapers to a smaller cross-section; or

- Contains any other recognized serious safety or health hazard.

By definition, a permit-required confined space program means (29 CFR 1910.146(b)):

- The employer’s overall program for controlling, and where appropriate, for protecting employees from, permit space hazards and for regulating employee entry into permit spaces.

If employees are expected to enter permit-required confined space, the facility must implement their permit space program. The facility’s written program should include the following for a safe permit space entry:

-

Equipment

- Have equipment available for safe entry into a permit space includes: testing, monitoring, ventilating, communications, lighting equipment, and retrieval devices.

-

Permit Program

- Must be signed by the entry supervisor.

- Must be posted at all entrances or otherwise made available to entrants before they enter a permit space.

- The permit must verify that pre-entry preparations outlined in the standard have been completed.

- The duration of entry permits must not exceed the time required to complete an assignment.

-

Training

- Must provide proper training for all workers who are required to work in permit spaces.

- Must ensure that the employees have acquired the understanding, knowledge and skills necessary to safely perform their duties.

-

Authorized Entrants

- Required to know space hazards, including information on the means of exposure such as inhalation or dermal absorption, signs of symptoms and consequences of the exposure.

- Must wear a chest or full body harness with a retrieval line, and other required equipment.

-

Attendant

- Required to remain outside the permit space during entry operations unless relieved by another authorized attendant.

- Perform non-entry rescues when specified by the facility’s rescue procedure.

-

Entry Supervisors

- Required to know space hazards including information on the mode of exposure, signs or symptoms and consequences.

- Must cancel entry permits when an assignment is completed or when new conditions exist.

-

Rescue Services

- Must provide rescue service personnel with personal protective and rescue equipment, including respirators, and training in how to use it.

-

If hazardous conditions are detected during entry...

- Employees must immediately leave the space, and evaluate the space to determine the cause of the hazardous atmosphere and modify the program as necessary.

-

Contractors

- Must inform contractors whom they hire to enter permit spaces about the hazards.

- Must ensure the contractors have a permit space entry program or the contractor must use the facility’s permit space program.

A permit-required confined space may be reclassified as non-permit confined space if the space poses no actual or potential hazards and if all the hazards within the space are eliminated without entry into the space.

If the facility can demonstrate with monitoring and inspection data that the only hazard is an actual or potential hazardous atmosphere that can be made safe for entry using continuous forced air ventilation, then it may be exempted from some permit space requirements, such as permits and attendants. However, the facility will test the internal atmosphere of the space for oxygen content, flammable gases and vapors, and the potential for toxic air contaminants before any employee enters it. The facility will provide continuous ventilation and verify that the required measurements are performed before entry.

If the entrance or portal is too small for a worker to completely enter a tank, or if the tank itself is too small for a worker to completely enter, then the space is not a confined space, thus a permit-required confined space entry program does not apply.

Need help with your next confined space entry project? Contact us now and let us put our expertise to work for you!

Related articles and information:

- Tradebe blog article "Tank Inspections 101"

- Tradebe Tank Cleaning services

__________________________________________

“Be Safe - Work Safe. Safety is No Accident!”

Jeremy Paradis, Director of Health & Safety, Tradebe USA

#Compliance #HealthandSafety #ConfinedSpaceEntry #BeSafeWorkSafe #SafetyisNoAccident

Resources:

Subscribe to Tradebe Safety Blog, news and more...

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.146

https://www.osha.gov/Publications/osha3138.html

At Tradebe, our priorities are safety and the protection of people and the environment. Safety is a common “water cooler” topic here at Tradebe where a culture of Safety is Top Priority. If Safety is important to your business, catch the latest buzz: Subscribe Now…